The worldwide manufacturing industry has been very active developing new projects supported by promotion funds and tax incentives across various sectors including semiconductors, electric vehicles, batteries, clean energy components (carbon capture, blue/green process), etc. Almost all of them involve the implementation of new technologies, which could be totally new for everybody or just for the Owner.

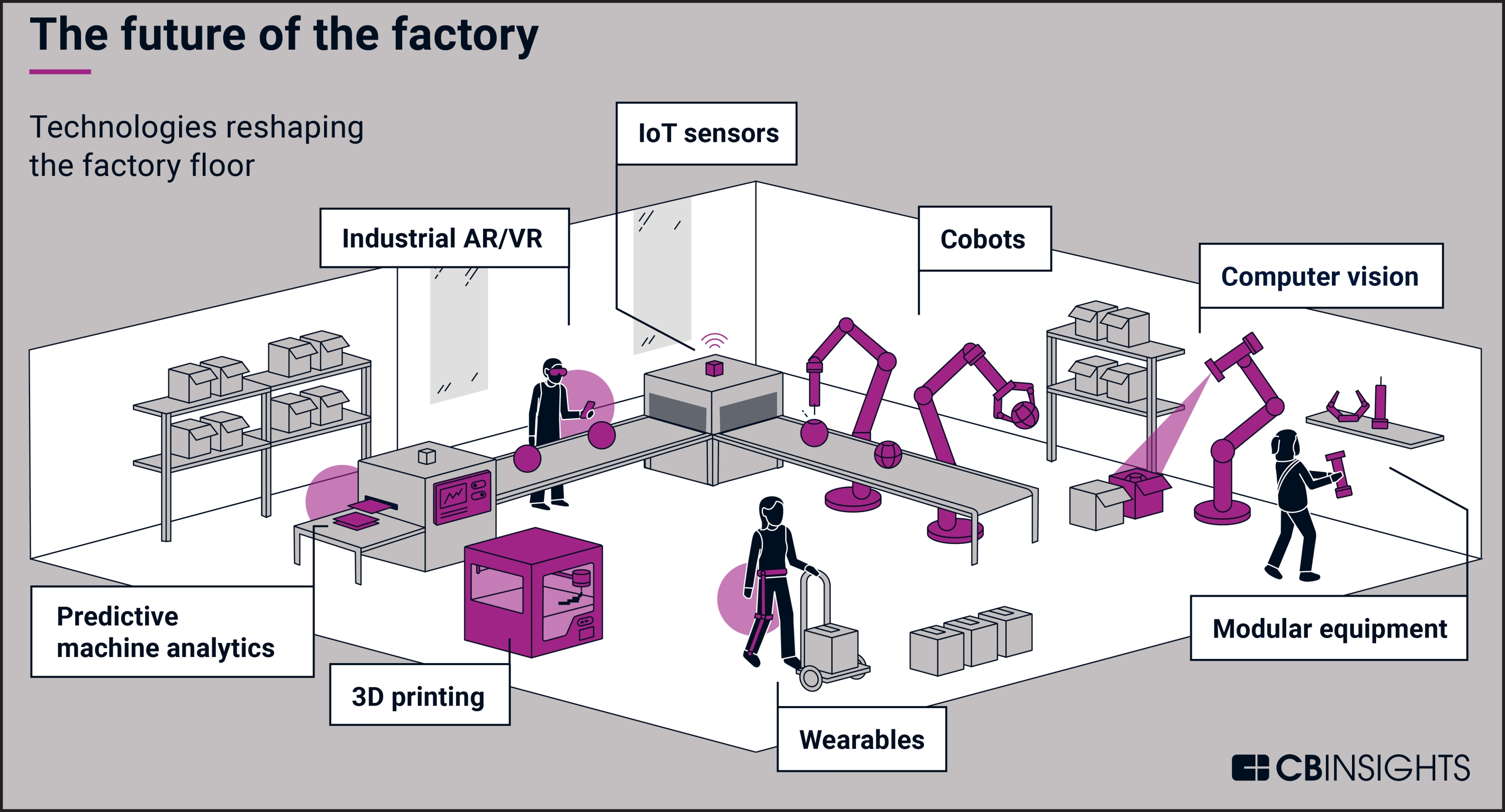

Technology is playing a significant role in supporting manufacturers in taking on the challenges they may face with new projects. Owners and contractors are looking for ways to improve efficiency and add value to the project cycle, construction methodologies, or their operations. Here are some examples:

- Applying digital transformation

- Embracing smart fabrications approach

- Exploring the industrial metaverse

- Investigating the possibilities of generative AI

Future generations will see how the combination of industrial metaverse and AI can boost productivity and address labor shortages. Experts expect AI to have immense potential in areas such as product design, aftermarket services, and supply chain management. Also, it is well known that robotics has made significant progress and is being implemented in all industries. The media hype has created unrealistic expectations for current technologies, causing us to overlook basic project management principles.

In this article, we will focus on implementing new technology projects and how to improve the key metric performance based on Industry Best Practices. Recent statistics show that less than 20% of projects using new technologies achieve the objectives agreed upon when they were approved. Their failures are very similar to the pitfalls of mega projects. Our findings derive from our combined research and consulting experience with our clients.

Some reasons why the execution of new technology projects fail include:

Unproven New Technology – Project Team and Stakeholders

Introducing unproven technology can lead to cost and time overruns. Project teams and stakeholders should recognize the value of the new technology in the project cycle, including its impact on the environment, safety, quality, operation, maintenance, and end-users.

- Internal Technology Development: Avoid a dual role between technological and implementation organization. Before moving from a lab to a commercial setup, create a prototype or pilot plant to test the technology in a controlled setting. This will help identify any potential challenges or limitations.

- R&D organization: Develops the technology to the point it is ready for implementation and then hands it off to the execution team. Both organizations overlap activities for a while. The execution manager must familiarize themselves with new technology, plan project execution, and ensure that the scope meets the needs of both developers and end users.

- Procured Technology: Before implementing new technology, it’s crucial to fully grasp its capabilities, challenges, and any unique considerations. Ensure stakeholders’ involvement and early contractor participation to define the most efficient process to execute the project.

Scope Creep

Poor communication, incomplete plans, and poorly defined scope can cause the project’s initial scope to expand beyond what was originally intended.

- Ensure that the project team and stakeholders have aligned expectations by documenting the scope, which includes the basic design data to support project development and operational performance. The importance of disciplined scope management and vigilance in evolving project dynamics safeguards adherence to the original vision and success within defined parameters.

Weak Change Management Process

It is necessary to have a stringent change control process that rigorously scrutinizes proposed modifications and prevents future setbacks. A clear scope baseline will serve as a reference, providing a foundation for evaluating the impact of changes.

- Adopting agile development with defined feature sets managed by a Scrum Master is recommended for projects with high levels of uncertainty, experimentation, and iteration. Remember, new technology projects have a higher occurrence of changes than standard technology projects.

- Adopt waterfall methods if the project is well-defined and has stable requirements and deliverables.

- Stakeholder engagement will prioritize early collaboration and comprehensive communication to mitigate risks associated with scope creep.

Business and Project Misalignment:

- Identify the specific requirements of the project, including the goals, scope, and timeline. Understand how the new technology fits into these requirements. And verify if it aligns with business and project objectives.

Lack of Effective Leadership:

Strong leadership is essential for setting the direction in project execution.

- Gather a team of knowledgeable and open-minded individuals who can learn and adapt to the technology, communicate effectively, collaborate well, and think creatively across different fields.

- Maintain clear communication with stakeholders, team members, and others involved in the project to ensure everyone is informed and working together. Ineffective communication can lead to misunderstandings, delays and reworks.

Unrealistic Plans

Excessive optimism and overcomplexity converge in a project plan that doesn’t have enough funding, time, people, or other key inputs.

- Develop a detailed project plan that outlines the tasks, milestones, and resources needed to implement the new technology.

- Monitor the project’s progress and evaluate the new technology’s performance to make sure it meets our desired outcomes.

- Select skilled suppliers and contractors based on a detailed and stricter due diligence of their capabilities.

- Make sure to accurately estimate costs and benefits to present the project in a more realistic and attractive way.

Inadequate Risk Management

New technologies are inherently risky, as they are often untested, unstable, or developing rapidly.

- To ensure project success, teams should identify and prioritize potential risks and uncertainties, like technical issues, compatibility problems, regulatory changes, or user resistance.

- Also need to develop and implement mitigation and contingency plans and monitor and review them regularly.

- Stakeholders must embrace change and flexibility in new technology projects and be ready to adjust plans to meet environmental, safety, operational, and market needs.

Pathfinder supports owner organizations with new technology projects, offering contracting strategies, project execution plans, and coaching to ensure successful completion.

Maria Lizardo

Maria is a Vice President with Pathfinder, LLC and has over 40 years of experience in the Oil & Gas Industry.

mlizardo@pathfinderinc.com

856-424-7100 x137